The brand new FULL AUTOMATIC PLATE MOUNTER from SysTec

T.H.E. MOUNTER

(T.H.E. = Total Human Exclusion)

Site map:

Plate mounters > Wide web flexo > T.H.E. MOUNTER

THE FIRST STEP TO A FULLY INTEGRATED FLEXO FACTORY

A look at the brand new FULL AUTOMATIC PLATE MOUNTER from SysTec

T.H.E. MOUNTER IS THE FIRST STEP TO A FULL INTEGRATED FLEXO FACTORY

T.H.E. MOUNTER is the revolutionary full automatic plate mounter

it has been introduced during the last Print4All expo held in Milano (Italy) on May 29th-June 1st 2018.

This is the first step for the visionary project "FULLY INTEGRATED FLEXO FACTORY"

PLATE MOUNTING HAS NEVER BEEN SO EASY

Discover T.H.E. MOUNTER

(T.H.E. = Total Human Exclusion)

Proud to introduce the real 4.0 mounter

Discover the new full automatic mounter from SysTec

In recent years some attempts to introduce a "fully automatic mounter" have been made, with some conflicting results: the technology is too expensive, the workflow is very complicated and rigid, the processes are delicate and vulnerable. In summary, while impressive in theory the technology does not really perform to the desire or expectations of the user.

We are glad to introduce the first real 4.0 plate mounter, based on SysTec's "Virtual Image" technology and experience.

The operative workflow of our machine is so easy with precision that the operation only requires the user to load the stack of plates on the loader... and that's it!

Focus on technology

Technological heart, human flexibility

- Robotic pick & place system

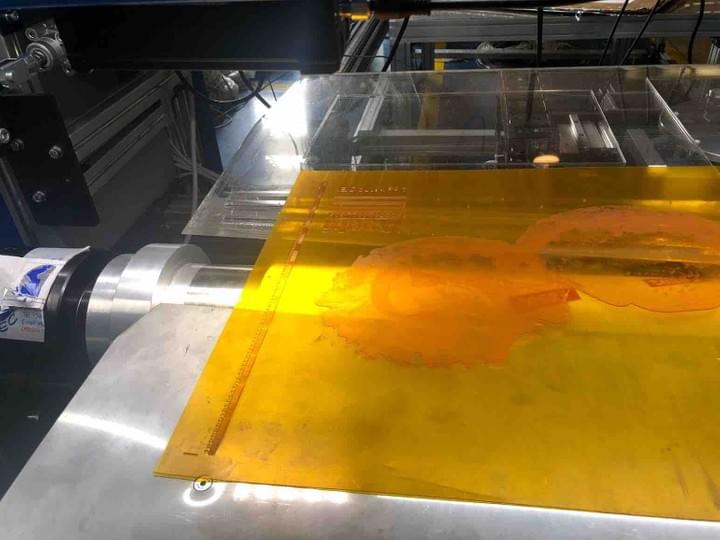

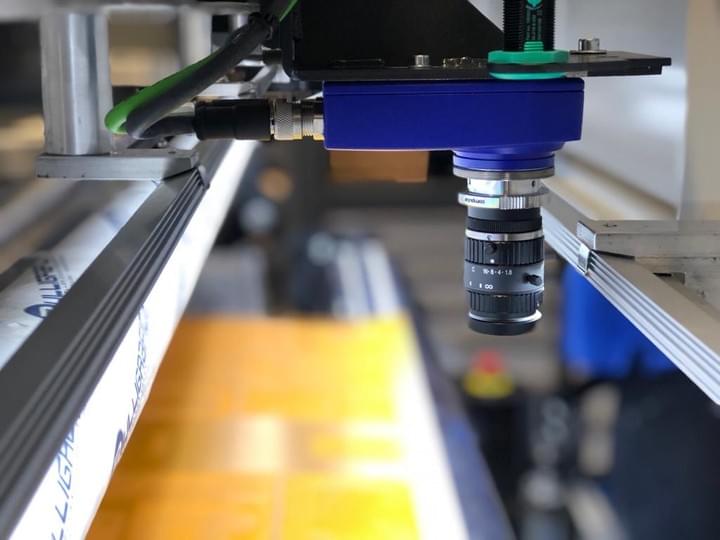

- Latest generation smart cameras, have the ability to recognize any kind of reference or registration target on the plates: any pattern can become reference for the following plate, with the "Virtual Image" technology

- Siemens electronics, for the fastest and most precise and reliable operation

How does it work?

This is why we named this machine "Total Human Exclusion"

The operator places the stack of plates on the loading deck, inserts the sleeves on the mandrel, and that's all! The machine automatically provides the following steps:

- Automatic loading of the plate from the deck

- Automatic discharge of the separating sheets

- Automatic positioning of the plate on the sleeve

- Automatic research/recognition of the marks on the plate

- Automatic adjustment of the plate to the target position

- Automatic fixing of the plates on the sticky-back with the pressing roll

Advantages

Just some ideas

- It works with any kind of cross-marks, targets or patterns on new and old plates

- High mounting precision +/- 0.005 mm (0.00019”)

- Reduction of the time needed to mount the plates

- Elimination of the human error while mounting the plates

- NO conveyor belt for loading the plates, so the operator is not busy in loading them into the machine

- Jobs repeatability

- The most 4.0 advanced technology available on the market

- It works 24/7

- The fastest ROI for this kind of machine

About iTABLE

The smart heart of the automatic mounter

iTable is an intelligent robotized table, it can move with 3 freedom degrees positioning the plates with centesimal precision.

It works in combination with advanced digital cameras, recognizing the cross-marks on the plates and automatically comparing them with the reference Virtual Image, and then adjusting the plate position on the sleeve.

The system provides the automatic positioning of the plates on the sleeve and the sticking of the plates on the tape with the automatic pressing roll.

- Contact Us

Fill the form to ask more information or to receive the brochure

Contact Us

SYSTEC CONVERTING

Powered by INKOMO

Via del Gelso 4

22100 Como

P.IVA 03715800136